Curler Rings, Segments and Large Profile Precision Tooling

Longer Service Life

Apex materials, processes and designs are all focused on providing high performance and long service life.

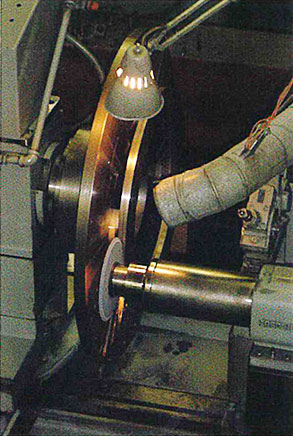

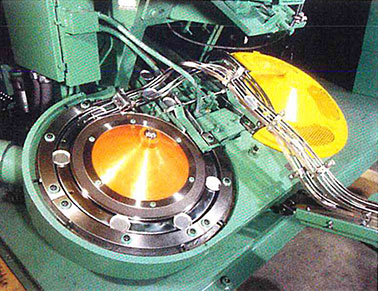

Curler tooling is manufactured from AISI 02 tool steel which is fully hardened. All curler ring grooves are ground with single-point, diamond-dressed wheels for optimum finish. The net result is a tool that will reliably hold its geometry for long, trouble-free operation.

The design of Apex curler rings also contributes to exceptional service life: Typically, both ring and segment are designed with two identical grooves, although only one groove at a time is used; when significant wear is detected, the tooling can easily be inverted so that the second groove can be utilized.

Made Right of Finest Materials

Apex also produces a broad range of other tooling for the container industry, all made from the finest quality carbide or tool steels, and all guaranteed to meet your exacting requirements:

- Blank and form dies

- Curler tooling

- Flanging dies and rings

- Beader rails and rolls

- Die cover plates

- Feed bars and fingers

- Lug cap tooling

- Pail head dies

- Ring and plug dies